Repair Tour

- Clocks are complex and it is very hard to predict what can be erroneous with them, but there are two main scenarios to fix the clock:

First Scenario:

- If your clock is not running because it has been relocated, mistreated, if you had kids playing with the pendulum, or if the wall clock slightly moved when you open the door for winding then most likely the clock is not "in beat", which can result in poor running, or even a stop. To make this clock "in beat" again, please see our "Helpful Hints" tab.

- Another common problem we see is a broken or twisted suspension spring, which also leads to the clock to stop. To fix it, the damaged part must be replaced.

- For Strike or Chime not in sequence, please call us first - sometimes it's possible to fix over the phone.

- Broken cable or chain.

- Hand collets loose, or hands touch dial/other hand when moving.

- Pendulum or crutch rubbing on case, etc.

- For most clocks, the above mentioned can be done in our shop or at the customer's house.

Second Scenario:

- If your clock was perfectly running for 25 years without any regular maintenance and then mysteriously stopped, it's not a big surprise. It is the equivalent of driving a car for years without ever getting an oil change. Clocks are mechanisms that require regular (every 2-3 years) maintenance.

- If not serviced, oil over time becomes dry and mixed with airborne dust, together they act as abrasive paste, which produces a lot wear on pivots and pivot holes. As a result, both pivots and pivot holes become worn, scored and out of shape. In this case there is no other option, but to do a complete overhaul.

- Don't trust anyone, who promise to fix your clock in this condition by cleaning and oiling. Placing clockwork in cleaning solution without taking it apart will only result in a shiny brass on the outside, but the internal problem of scored pivots and worn-out pivot holes will still remain. This isn't the proper way to fix a clock and your clock will not operate for very long. To restore your clock to excellent operating condition a complete overhaul must be done in a professional clock shop only.

- This is based on the percentage of work we do, but it doesn’t cover every aspect of clock repair. To find out why your clock is not running properly please call us 720-935-2645 for free in shop consultation.

Complete Overhaul Procedure:

We offer a two year guarantee on all overhauls

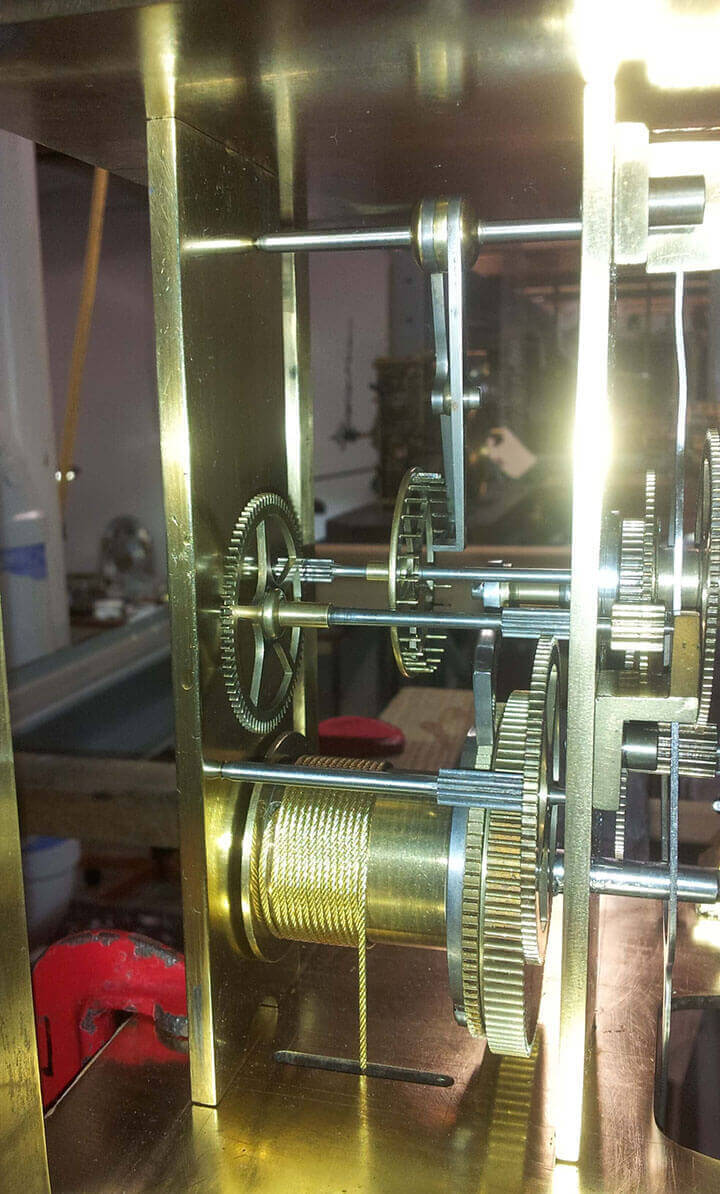

| Step 1: | Examine and repair broken and worn-out parts |

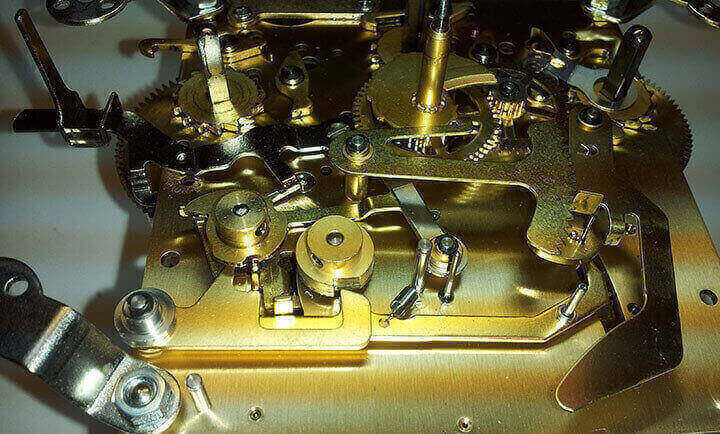

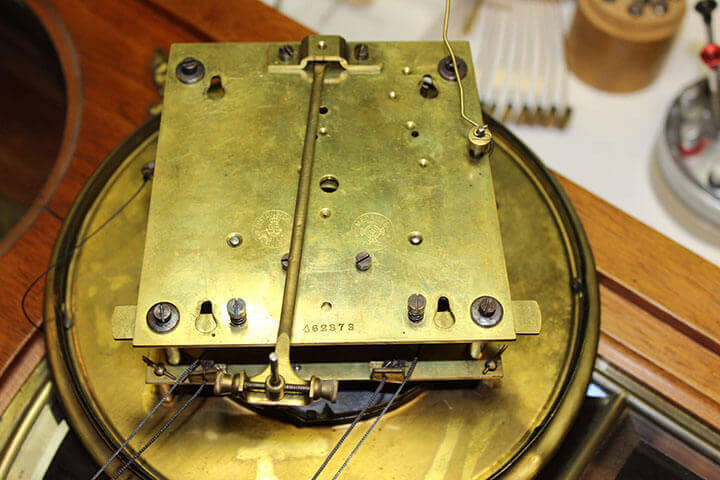

| Step 2: | The movement will be completely dismantled (taken apart) |

| Step 3: | All parts will be ultrasonically cleaned and any rust or corrosion will be removed |

| Step 4: | Repairing and polishing worn-out pivots, then burnishing them to mirror finish. To achieve this we use a 20X microscope to make sure there are no blemishes left behind |

| Step 5: | All worn-out pivot holes will be re-bushed with high quality Swiss made Bergeon or KWM bushings (we have both systems available) |

| Step 6: | Escapement will be polished and adjusted if needed |

| Step 7: | Mainspring will be out from the barrel, cleaned, checked for defects, and re-oiled |

| Step 8: | All gears will be tested individually for endshake, sideshake and in pairs for correct depthing |

| Step 9: | Pivot holes cleaned with peg wood and all parts re-cleaned |

| Step 10: | Movement is reassembled with gloves to prevent any fingerprints |

| Step 11: | Striking and chime systems setup (if equipped) |

| Step 12: | All moving parts will be lubricated with high grade clock oil and grease |

- Final Step: Clock movement will be tested and regulated for 2 weeks before being set up in its case.

Please visit our Facebook for weekly updates,

repair highlights, buy and sell